Easy design of thermal oil pipeline systems with maxxCALC 1.0

Planning thermal oil systems requires a lot of information and experiences. Failures can cause high cost during the installation and operation of a plant.

Most engineers and technicians do not deal with the matter very often and if you do have to do it, it is tedious all regardless of whether you are planning, reviewing or currently installing a system, the necessary data and technical background information research is time-consuming.

maxxCALC1.0 has been developed to help you determine the essential information for planning thermal oil piping systems in an easy way.

What features can you expect?

maxxCALC 1.0 calculates volume flows, temperatures, pipe- and flange dimensions, safety valve specifications and more. It offers several types of thermal fluids, and it considers if nitrogen blanketing is used or not.

The program is divided into 4 main sections, which should be self-explaining. After you have calculated the oil flow and the pipe dimensions, they will be visualized in a P&ID. This allows you to see the results in the context of the complete primary cycle.

P&I Diagram

This sheet shows a process and instrumentation diagram of a maxxtec thermal oil plant where the calculation results are visualized. (*see Figure 2)

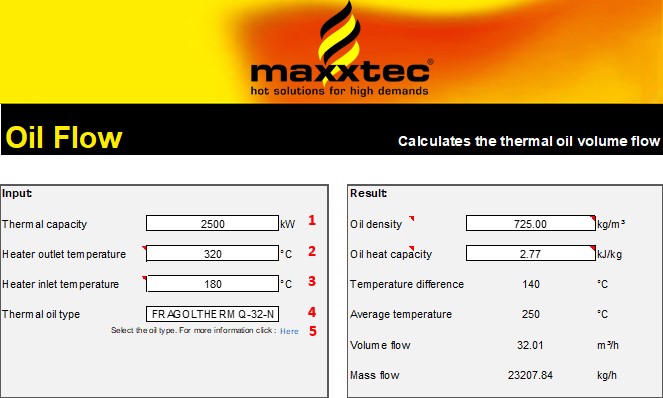

Oil Flow

The ‘thermal oil type’ can be chosen by selecting it in the drop-down menu. It consists of a variety of thermal oils covering most applications, including food grade and high temperature application. If more information to these thermal oils is required, click the link under (5). (*See Figure 4)

Dimension

Selects the dimension of the thermal oil auxiliary, like expansion-, venting- and overflow pipes. The basis is the DIN 4754, the German standard for heat transfer plants with organic heat transfer fluids which is common in most countries.

The calculated values and changes of N2 blanketing will be shown in the P&I Diagram.

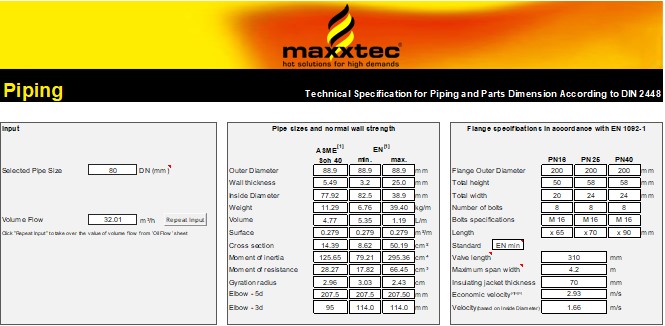

Piping

Determines the technical specification for piping and flange connections in your system according to EN 10216 / DIN 2448. It gives you the main information of pipe and elbow, valve length, maximum width within supports and information about flanges and bolts.

Choose the selected pipe size if it is already known, to calculate the economic volume flow. You can change the unit from ‘mm (DN)’ to ‘inch’ in the drop-down menu. (*See Figure 9)

Alternatively, type in your required volume flow to calculate the suitable pipe size.

The economic volume flow refers to the most cost-efficient volume flow considering capital cost and operating cost.

In the right section you will find the related flange specifications and dimensions. Find also other information for your piping, such as installation length of valve, span width between supports, insulation thickness, and velocity.

Notes

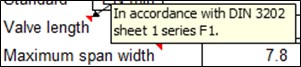

In this program, you will find cells that are marked with a red triangle shape on the top right. These cells contain information notes, which are helpful when using the program.

Share it with your colleagues or partners for whom this program could be useful.

CONTACT

PT Maxxtec Teknologi Indonesia

ITC Permata Hijau, Lantai 3 C11 No. 16,

Jl. Arteri Permata Hijau, Kebayoran Lama,

12210 Jakarta Selatan

Indonesia

Telephone: +62-21-53670749

Service: +62-812-82506215

Email: teknologi@maxxtec.co.id